Fast prototyping

Building and testing prototypes can easily delay a project. Design flaws in a prototype may mean that an additional prototype needs to be constructed. Such iteration steps have to be avoided as much as possible. Often, it is easier to work with a simulation model than to work with prototypes. We reduce the prototyping work as much as possible, yet often it is quite essential for obtaining good results.

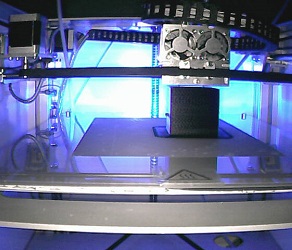

Outsourcing the production of electronics may result in more than a month of lead time. Z.E.S. has an agreement with a production facility that helps to speed up the assembly of PCB’s. Prototype enclosures and mechanical parts can often be quickly realized with 3D printing.