New instrument for (robotic) ultrasonic inspection

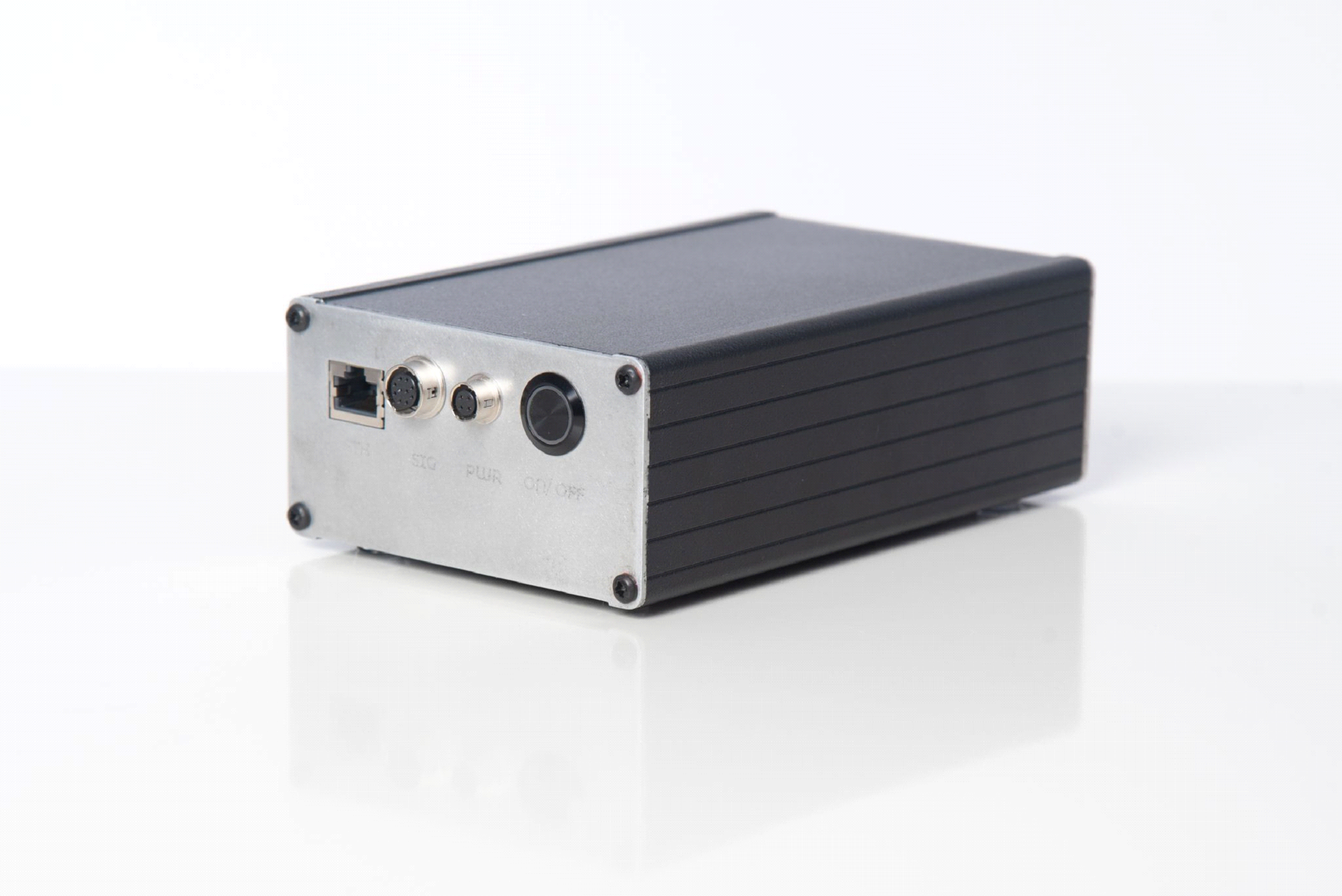

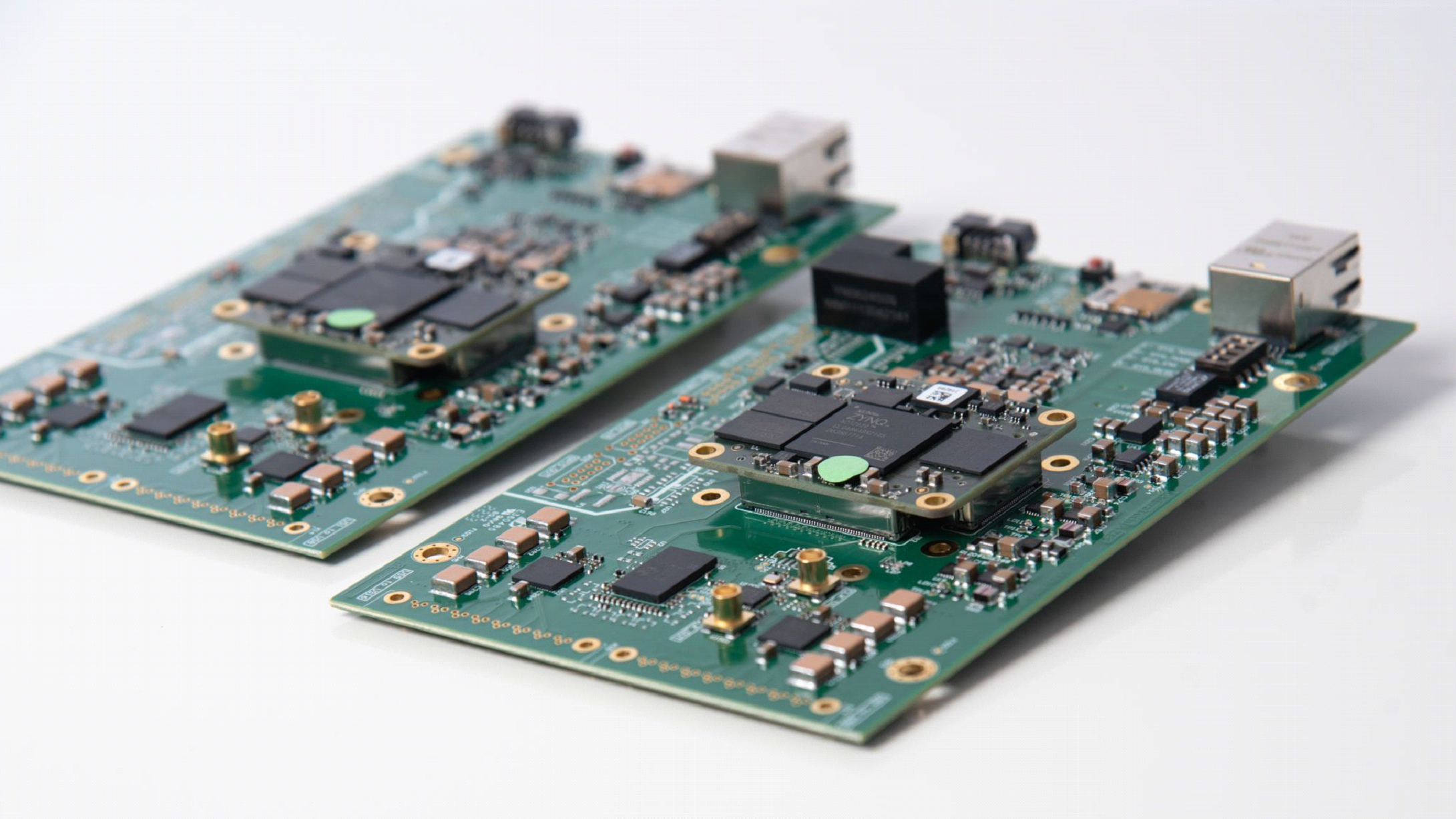

Ultrasonic inspection is used for finding production defects in materials and also for finding material degradation in objects that are in use. Inspection tasks can be difficult or even dangerous, which makes it attractive to use robots for these tasks. However, you do need ultrasonic instrumentation that can be fully integrated with the electronics and software used by the robot. In a collaboration between Z.E.S., Schirratech (electronics), and Creative Embedded (software), we developed such an UT instrument. It has strong I/O capabilities and much computational power for embedded signal processing.

Our flexible 16ch UT system can serve several applications as it is configurable as:

-> 1 to 16 channels pulse echo (serial or parallel)

-> 1 to 8 channels ToFD

-> FMC mode

-> Play mode (do whatever you like)

𝐊𝐞𝐲 𝐩𝐚𝐫𝐚𝐦𝐞𝐭𝐞𝐫𝐬:

– 10 to 65MSa/s at 14bits

– 2:1 multiplexer

– 1000Mbit Ethernet

– 3-axis encoder input

– External trigger input

– RS422

𝐎𝐭𝐡𝐞𝐫𝐬:

– Customization for specific application is also possible.

– Python control core and simple example freely available.

– API freely available (can be customized on request).

– Support for software development available: C/C++, Python, Labview, VHDL

– Connectors and enclosure optional and customizable.

The pictures show the system in an enclosure that is more suited for development and lab applications.

IMRIE

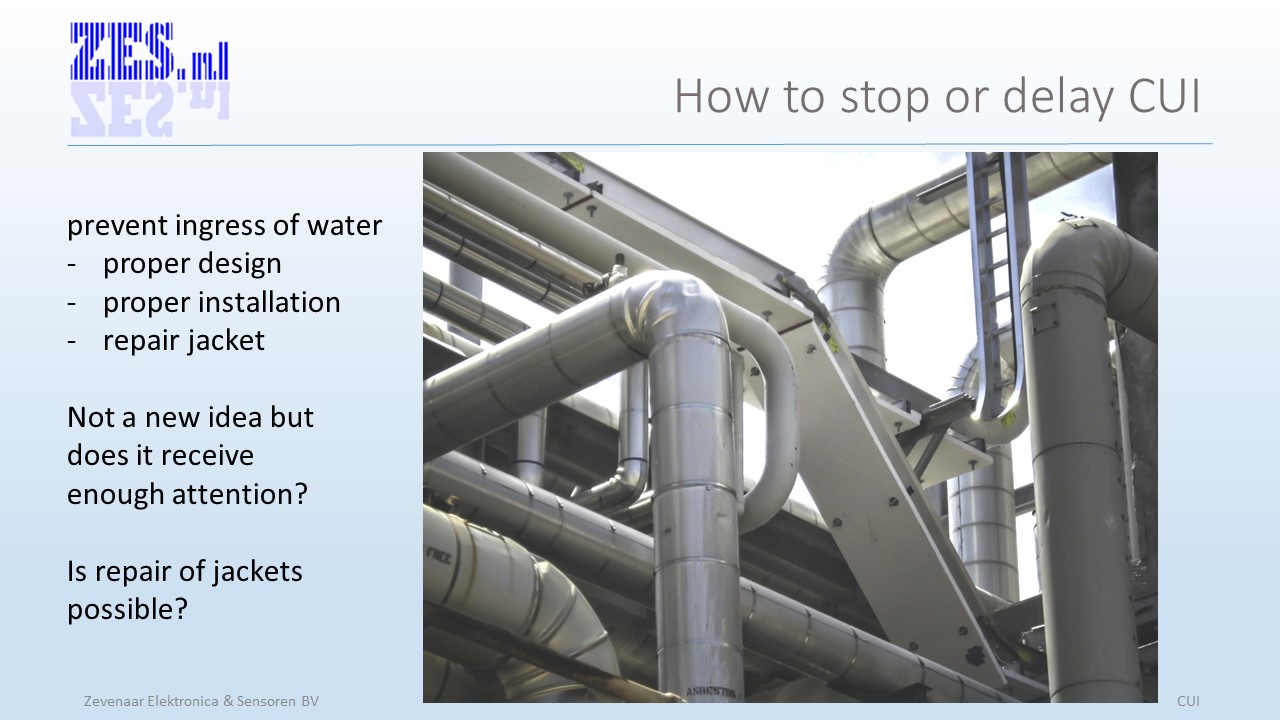

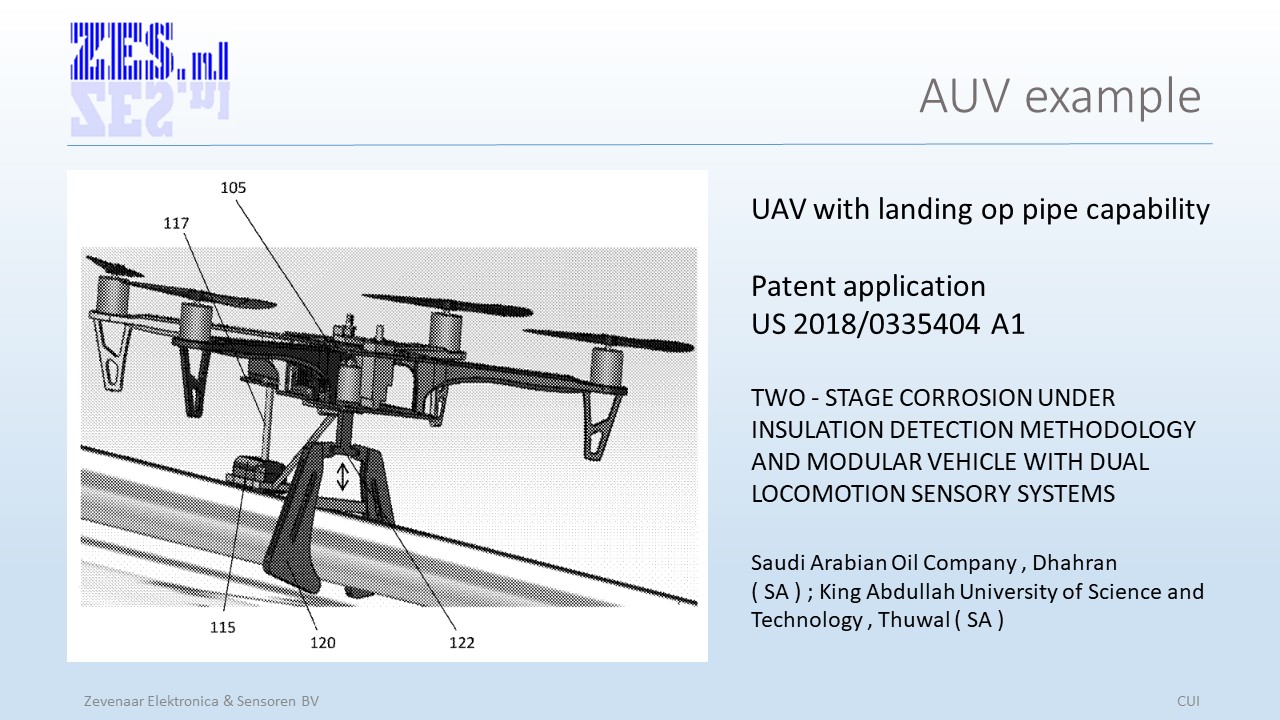

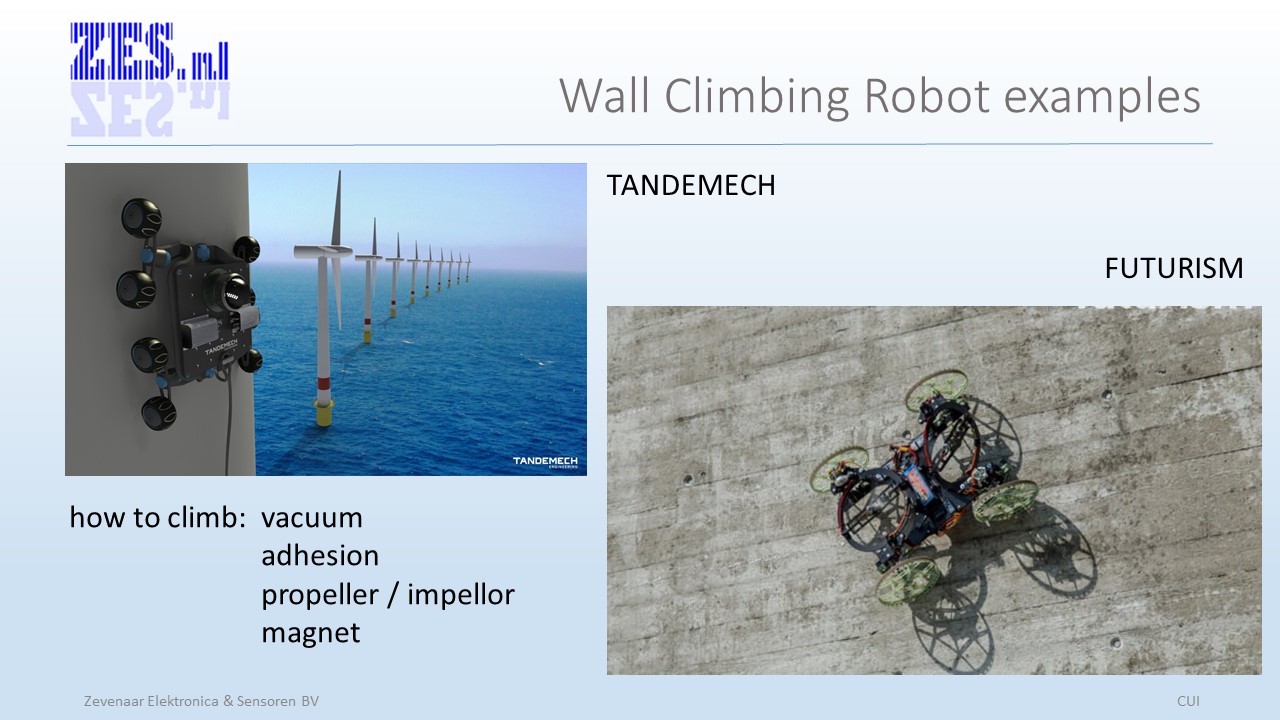

Development of an Inspection and Maintenance Robot for Insulated Equipment

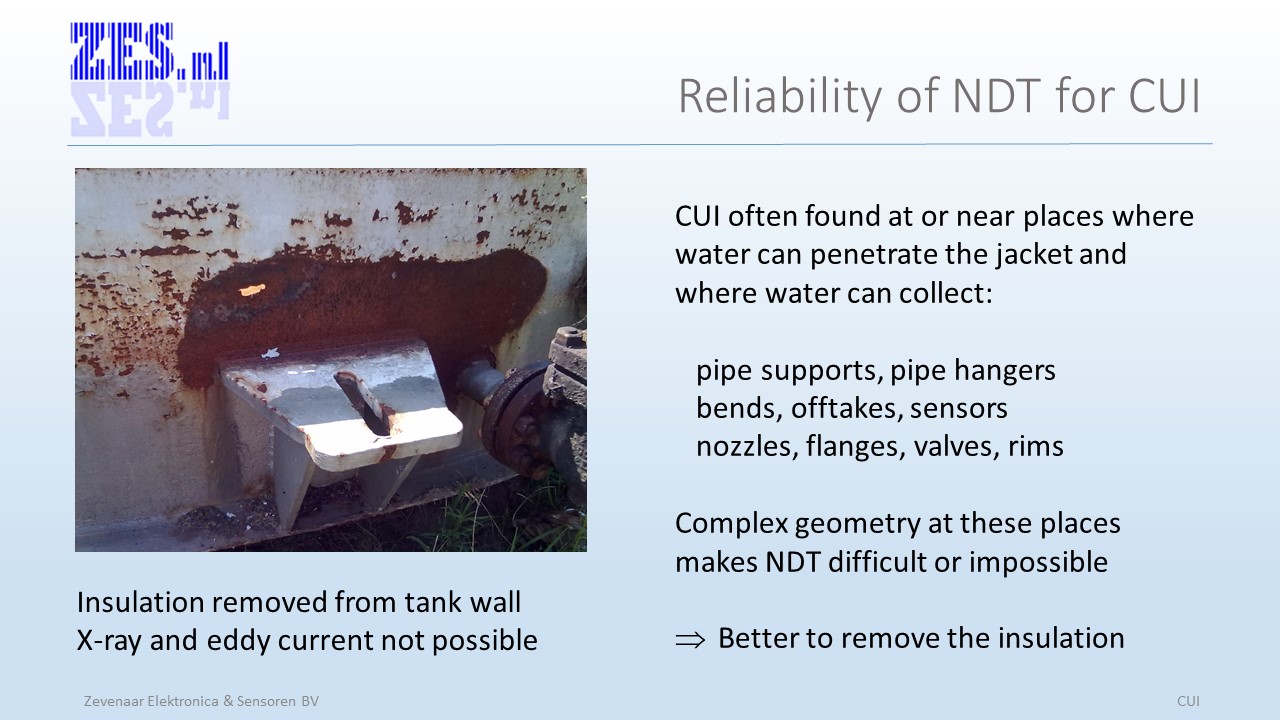

Corrosion Under Insulation (CUI) is a serious problem for outdoor process equipment (e.g. at refineries, chemical plants, offshore installations). Water that penetrates the insulation can cause corrosion in pipes, vessels and storage tanks. This corrosion is not visible from the outside and has been responsible for numerous corrosion accidents. Many techniques have been developed to detect the corrosion without having to remove the insulation. Yet these techniques are limited in their capabilities, and do not offer an effective remedy. Therefore we have developed an alternative approach, using the rapid developments in the area of robotics.

Pipeline inspection 2017

Project to study and develop new sensors for pipeline inspection. The project is carried out with the help of students from the HAN faculty of engineering. Project promotor is Somatidio.